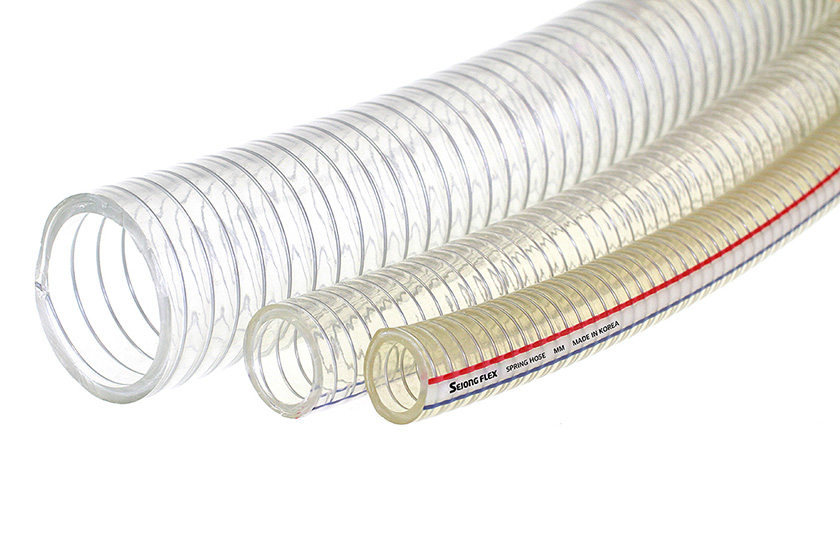

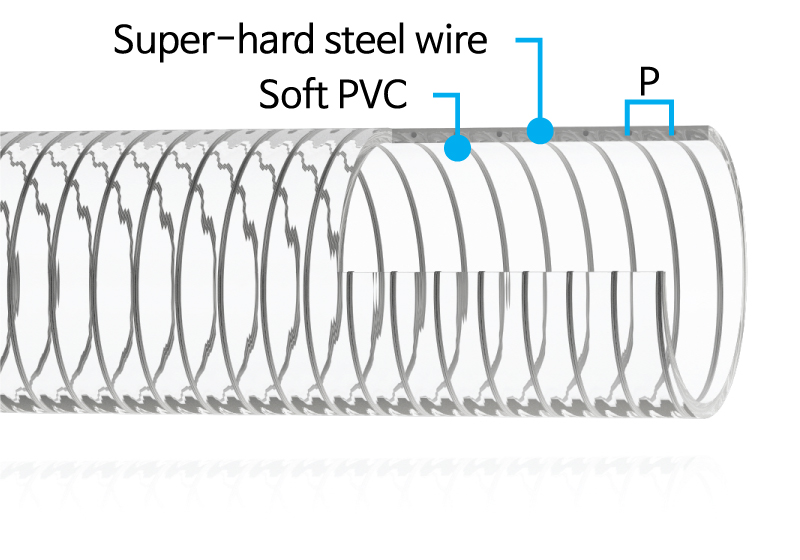

Discover unparalleled industrial solutions at Pusaco Industrial Supplies. Specializing in Matsushima conveyor protection, pull cord switches, belt sway switches, and speed switches, we bring you cutting-edge products for optimal safety. Explore our range of Exen flow aid systems and air knockers, Perma Flex Plus, and Perma Star Vario for reliable lubrication solutions. Elevate your operations with precision-engineered Rexnord table top chains, mat top chains, and conveyor table top chains. Our SejongFlex offerings include PVC food-grade spring hoses and braided hoses, ensuring versatility in your industrial applications. Trust in the durability of PTI disc couplings, grid couplings, and gear couplings, as well as the flexibility provided by KwangJin rotary and swivel joints. Enhance stability with MK shock absorbers casters, and navigate industrial environments seamlessly with Amaco caster wheels. Your comprehensive source for industrial supplies, we pride ourselves on delivering excellence in every product category.